SS 316L Kammprofile Gasket

All SS 316L, SS304, Monel 400, Inconel 600, Incoloy 800 and carbon steel Kammprofile Gaskets can be offered

Content

What is SS 316L Kammprofile Gasket

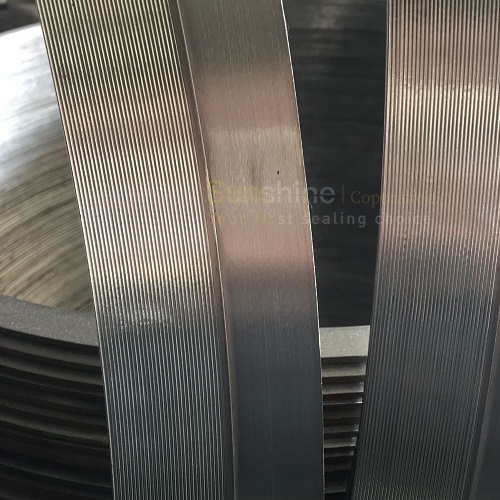

SS 316L Kammprofile gasket consists of a SS 316L metal core with concentric grooves on either side with sealing materials. The sealing layers (depending on the service duty) can be Graphite, PTFE (Teflon), Non-asbestos. Kammprofile gasket can be used without sealing layers to provide an excellent seal but there is a risk of flange surface damage.Typical Applications

The very wide seating stress range (minimum to maximum stress) of the SS 316L Kammprofile gasket makes it highly suitable for varying temperatures and pressures., Less senstive to assembly faults, suitable for light and heavily constructed flanges. Dependent on layer material SS 316L Kammprofile gasket is resistant to temperatures up to 1000°C and media pressures up to 250 barThe additional Benefits and Advantages

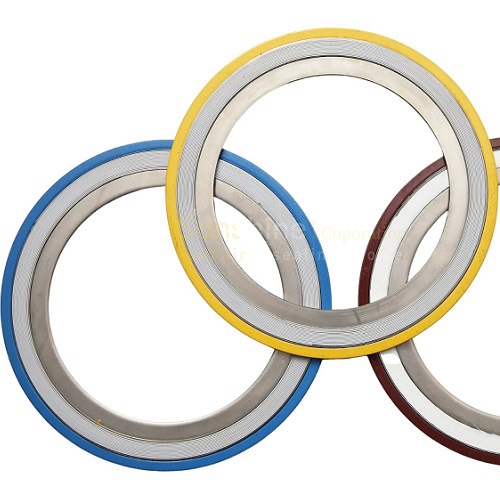

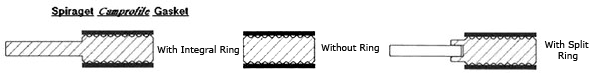

When assembled the layer thickness of the sealing material is extremely small (0.5mm) thus reducing leaks, reject rates and environment pollution. The SS 316L Kammprofile gasket will not damage the flange surface and can be easily removed and it also reduces maintenance costs. Flange face protection Kammprofiles will not damage the flange faces even at extreme seating load. SS 316L Kammprofile gasket has excellent performance when subject to fluctuating temperatures and pressures. It is a direct replacement gasket for existing gaskets, no special flange finish is necessary. SS 316L Kammprofile gasket is an eco-friendly gasket by significantly reducing leakage into the atmosphere. The recommended flange surface finish for Kammprofile gasket with sealing layers is from 125 to 250 RMS.SS 316L Kammprofile Gasket with Loose or Integral rings

Thermal-shock conditions may damage Kammprofiles with integral centering rings (thermal tension may cause cracks in the core).

Sealing Layer Materials and Sealing Stresses

The following table gives information regarding different types of layer materials of Kammprofile Gasket. Also given is recommended seating stress range for reliable and effective performance.

|

Material |

Temp (°C) |

Max Operating pressure |

Gas Tightness |

Application |

|

Graphite |

- 200 - 550 |

250 bar |

Good |

Aggressive Media |

|

PTFE |

-260 - 260 |

100 bar |

Good |

Aggressive Media |

|

Non-asbestos |

-80 - 300 |

100 bar |

Good |

Liquids |

Metal Core thickness of Kammprofile Gasket

When a Kammprofile gasket is replacing an existing gasket such as spiral wound gasket, we recommend a 4mm thick core to prevent unnecessary stresses on existing pipe lines. For new system, we recommend 5 mm thick cores. The value should be taken into account at the design stage.

Related Category

CGI Spiral Wound Gasket

CG Spiral Wound Gasket

Vermiculite Filler Spiral Wound Gasket

Raw Materials for Spiral Wound Gasket

OFHC Copper Gasket For CF Flanges

Flange Isolation Gasket Kits

Rubber-steel Flange Gaskets

Ring Type Joint Gasket

Kammprofile Gaskets

Related Products