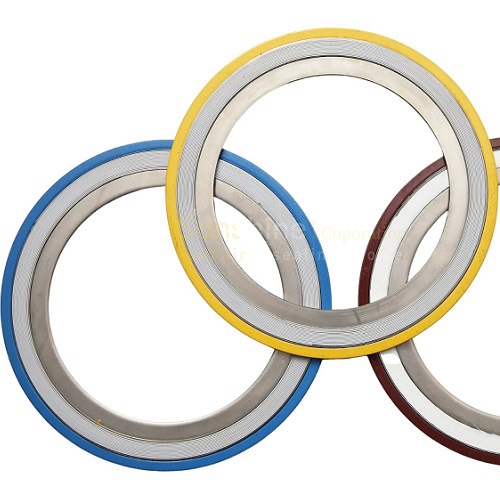

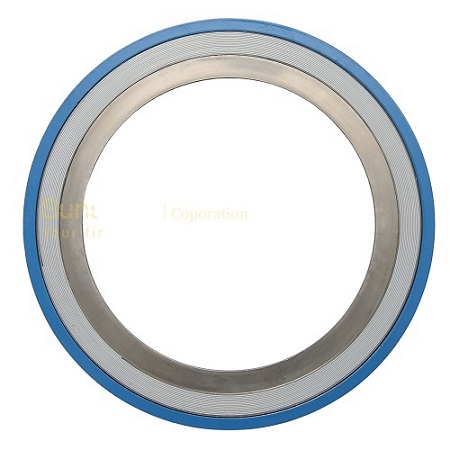

SS 316L with Graphite Filler Spiral Wound Gasket

SS 316L with graphite filler spiral wound gasket is a very normal gasket and widely used in oil and gas areas. Factory price and short delivery time

Content

Quick Overview

SS 316L with graphite filler spiral wound gasket is made of V-shape stainless steel SS 316L and soft graphite filler, with inner and outer ring. This material spiral wound gasket can be used in severe corrosive and high temperature environments, it has improved anti–corrosion scope due to added Molybdenum. And it is a very common and economical spiral wound gaskets, and as the supplier and manufacturer of spiral wound gaskets, we can offer you factory price in short delivery time.And for 316L stainless steel, it is a type of metallic alloy of stainless steel that is austenitic and contains nickel and molybdenum, which make it corrosion resistant. It has low carbon content eliminates carbon precipitation in the welding process and it is very similar to Grade 316 in chemical composition and mechanical properties.

What Is the Advantage Of SS 316L with Graphite Filler Spiral Wound Gasket?

SS 316L with graphite filler spiral wound gasket is the regular molybdenum-bearing grade second in importance to SS 304 among the austenitic stainless steels. Molybdenum provides 316 better overall corrosion-resistant properties than Grade 304, particularly higher pitting resistance and chloride crevice corrosion.SS 316L with graphite filler spiral wound gasket is resistant to sensitisation (precipitation of grain boundary carbide), a low carbon variant of 316. It is therefore widely used in high-gage (over 6 mm) welded parts. Usually, there is no significant price difference between 316 and 316L stainless steel.

Which is more expensive SS304 or SS316?

The increase of nickel content and the addition of molybdenum in 316 makes it more expensive than 304. On average, the price of 316 stainless steel 40% higher than the price of 304 SS

Chemical Analysis of SS 316L (%)

| Cr | P |

Ni ≥ |

C ≤ |

Mn ≤ |

Si ≤ |

S ≤ |

Mo ≤ |

| 16 to 18 | 0.045 | 10 - 14 |

0.03 |

2 | 1 | 0.03 | 2 - 3 |

Mechanical Properties of SS316L

|

Ultimate Tensile Strength (Mpa) |

Elongation % |

Yield Strength MPa |

Density g/cm3 |

|

485 |

52 |

205 |

7.9 |

Related Category

CGI Spiral Wound Gasket

CG Spiral Wound Gasket

Vermiculite Filler Spiral Wound Gasket

Raw Materials for Spiral Wound Gasket

OFHC Copper Gasket For CF Flanges

Flange Isolation Gasket Kits

Rubber-steel Flange Gaskets

Ring Type Joint Gasket

Kammprofile Gaskets

Related Products