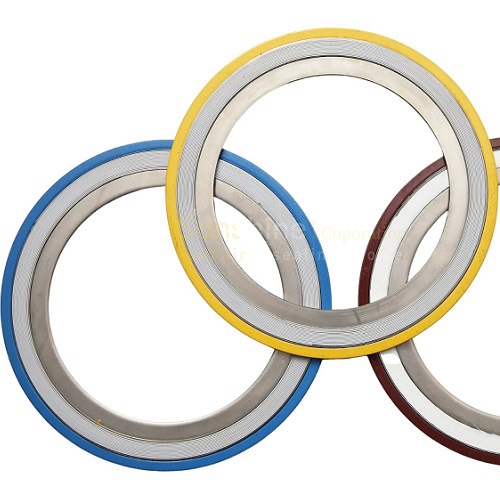

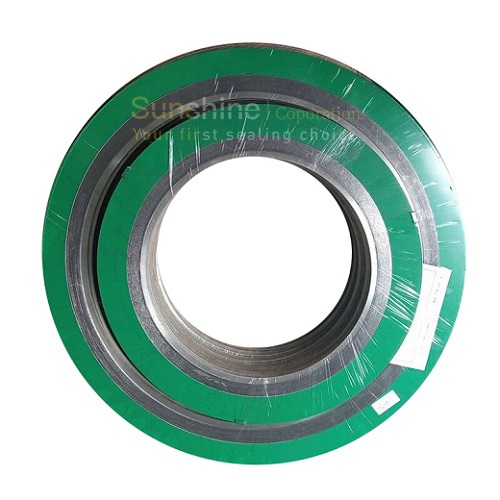

Super Duplex S32750 Spiral Wound Gasket

Super Duplex UNS S32750 is the most common super duplex grade in the market.

Content

What is Super Duplex S32750 Spiral Wound Gasket?

Super duplex S32750 spiral wound gasket consists of a winding ring made of V-shape S32750 strip and PTFE or graphite filler, then combined with an inner ring or outer centering guide ring. Super duplex S32750 spiral wound gasket has very high strength, very good resistance to pitting and crevice corrosion and excellent resistance to chloride stress corrosion cracking.What is S32750?

S32750 is the standard grade of super-duplex stainless steel based on 25% chromium, 7% nickel and significant additions of molybdenum, manganese and nitrogen. As with many of the duplex grades, S32750 also offers high strength and excellent resistance to chloride stress corrosion cracking, while the molybdenum and nitrogen levels enhance the pitting, crevice and general corrosion resistance.Super Duplex S32750 Spiral Wound Gasket Applications

Super duplex S32750 spiral wound gasket is primarily used in the oil and gas industry, particularly for offshore platforms, heat exchangers, structural components, and architectural components, pipe flanges, Oil and gas production, Pulp and paper.Chemical Composition of S32750 (%)

| Cr | Mo |

Ni ≥ |

C ≤ |

Mn ≤ |

Si ≤ |

S ≤ |

Cu ≤ |

| 24 - 26 | 3 - 5 | 6 - 8 |

0.03 |

1.2 | 0.8 | 0.02 | 0.5 |

Mechanical Properties of S32750

|

Ultimate Tensile Strength (Mpa) |

Elongation % |

Yield Strength MPa |

Density g/cm3 |

|

850 |

24 |

590 |

7.8 |

Related Category

CGI Spiral Wound Gasket

CG Spiral Wound Gasket

Vermiculite Filler Spiral Wound Gasket

Raw Materials for Spiral Wound Gasket

OFHC Copper Gasket For CF Flanges

Flange Isolation Gasket Kits

Rubber-steel Flange Gaskets

Ring Type Joint Gasket

Kammprofile Gaskets

Related Products