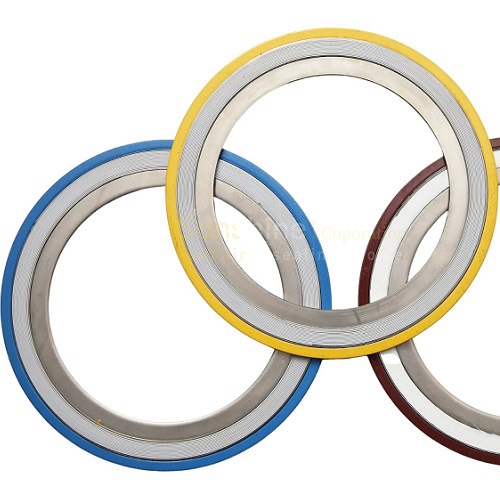

SS 321 Spiral Wound Gasket Graphite Filled

SS 321 spiral wound gasket graphite filled is made of quality V-shape materials and graphite tape filler

Content

What is SS 321 Spiral Wound Gasket Graphite Filled?

SS 321 spiral wound gasket graphite filled is made of V-shape SS 321 strip tape and graphite tape filler, SS 321 spiral wound gasket with graphite filled is the grade of choice for applications in the temperature range of up to about 900°C, combining high strength, resistance to scaling and phase stability with resistance to subsequent aqueous corrosion. It is used primarily in oil refinery equipment, pressure vessel piping, radiant superheaters, bellews, and high-temperature heat treatment equipment.Stainless Steel 321 is a basic austenitic 18/8 steel (Grade 304) stabilised by Titanium (321) addition. SS 321 is used because they are not sensitive to intergranular corrosion after heating within the carbide precipitation range of 425-850°C.

Key Properties of Stainless Steel 321 Spiral Wound Gasket

SS 321 spiral wound gasket is well used in high temperature service, it has higher creep and stress rupture properties than type 304 gasket and high resistance to corrosion.Applications of SS 321 Spiral Wound Gasket

Typical applications of SS 321 spiral wound gasket graphite filled include aircraft exhaust manifolds, expansion joints, furnace parts, Heating element tubing, Heat Exchangers and high-temperature mineral processingCorrosion Resistance of SS 321

SS 321 is equivalent to grade SS 304 in the annealed condition, and superior if a weldment in these grades has not been post-weld annealed or if the application involves service in the 425 - 900 °C range. Subject to pitting and crevice corrosion in warm chloride environments, and to stress corrosion cracking above about 60 °C. Considered resistant to potable water with up to about 200 mg/L chlorides at ambient temperatures, reducing to about 150 mg/L at 60 °C.Chemical Analysis of SS 321(%)

|

Ultimate Tensile Strength (Mpa) |

Elongation % |

Yield Strength MPa |

Density g/cm3 |

|

600 |

45 |

275 |

7.94 |

Related Category

CGI Spiral Wound Gasket

CG Spiral Wound Gasket

Vermiculite Filler Spiral Wound Gasket

Raw Materials for Spiral Wound Gasket

OFHC Copper Gasket For CF Flanges

Flange Isolation Gasket Kits

Rubber-steel Flange Gaskets

Ring Type Joint Gasket

Kammprofile Gaskets

Related Products