Nickel 200 Spiral Wound Gasket

Nickel 200 and Nickel 201 are solid solution strengthened, commercially pure wrought materials with good mechanical properties over a wide range of temperatures and excellent resistance to many corrosives

Content

What is Nickel 200 Spiral Wound Gasket?

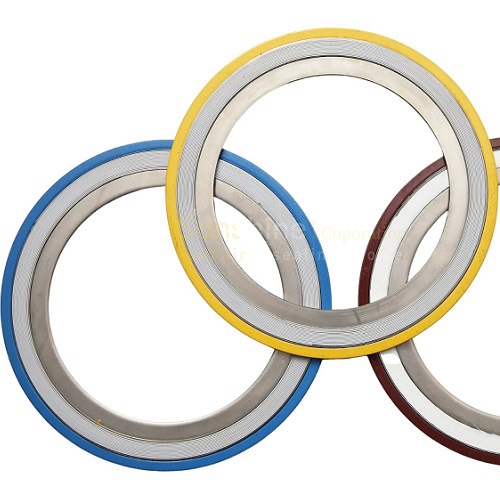

Nickel 200 spiral wound gasket consists of a winding ring made of V-shape Nickel 200 tape strip and PTFE or graphite filler, then combined with an inner ring or outer centering guide ring. Nickel 200 spiral wound gasket has exceptional resistance to caustic alkalis at different concentrations and temperatures, Its thermal and electrical conductivities are higher than nickel alloys spiral wound gasket.Applications of Nickel 200 Spiral Wound Gasket

Nickel 200 spiral wound gasket can be used in food processing equipment, Drums to transport chemicals, piping and equipment used in conjunction with alkalis, Handling of foods, aerospace and missile components.What is Nickel 200?

Nickel 200 is a 99.6% pure nickel alloy and one of the toughest metals in existence. It exhibits excellent mechanical properties and high thermal and electrical conductivity. Additionally, Nickel 200’s beneficial properties and its chemical composition make it easily fabricable and highly resistant to corrosive environments.Nickel 200 Advantages

Nickel 200 is a 99.6% pure nickel alloy, is useful in any environment below 600º F. It is highly resistant to corrosion by neutral and alkaline salt solutions. Nickel alloy 200 also has low corrosion rates in neutral and distilled water. This nickel alloy can be hot formed to any shape and formed cold by all methods. Additional benefits include: Excellent mechanical properties, Low gas content, Low vapor pressure, High thermal and electrical conductivityThe Resistance of Nickel 200 to Corrosion

Nickel 200 offers excellent corrosion resistance in reducing and neutral media as well as in oxidizing atmospheres, provided the oxidizing media allows the formation of a passive oxide film. This oxide film accounts for the alloy's excellent resistance to corrosion in caustic environments. Nickel 200 is often used in environments containing alkalies, and it has varying use in sulfuric, hydrochloric, anhydrous hydrofluoric and non-aerated organic acids.

Chemical Analysis of Nickel 200 (%)

| Ni | Mo | Fe ≤ | C ≤ | S ≤ | Cu ≤ | Mn ≤ | Si ≤ |

| 99 | 26 - 32 | 0.4 | 0.15 | 0.001 | 0.25 | 0.35 | 0.35 |

Mechanical Properties of Nickel 200

| Ultimate Tensile Strength (Mpa) | Elongation % | Yield Strength MPa | Density g/cm3 |

|

530 |

39 |

355 |

8.9 |

Related Category

CGI Spiral Wound Gasket

CG Spiral Wound Gasket

Vermiculite Filler Spiral Wound Gasket

Raw Materials for Spiral Wound Gasket

OFHC Copper Gasket For CF Flanges

Flange Isolation Gasket Kits

Rubber-steel Flange Gaskets

Ring Type Joint Gasket

Kammprofile Gaskets

Related Products