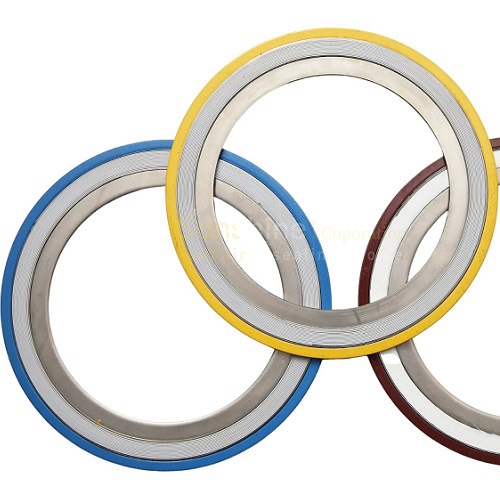

Inconel 625 Spiral Wound Gasket

Inconel 625 Spiral Wound Gasket resists a wide range of temperature extremes from cryogenic to extremely high

Content

What is Inconel 625 Spiral Wound Gasket?

Inconel 625 spiral wound gasket is made of Alloy 625 steel strip and soft filler such as graphite and PTFE, it has high strength and outstanding aqueous resistance to chloride pitting and crevice corrosion. The strength of alloy 625 spiral wound gasket is primarily a solid solution effect from molybdenum and columbium.Applications of Inconel 625 Spiral Wound Gasket

Inconel 625 spiral wound gasket can be used in aircraft ducting systems, jet engine exhaust systems, engine thrust-reverser systems, bellows and expansion joints, seawater components.Corrosion Resistance of Inconel Alloy 625

Inconel alloy 625 has withstood many corrosive environments. In alkaline, salt water, fresh water, neutral salts, and in the air, almost no attack occurs. The nickel and chromium provide resistance to oxidizing environments. Nickel and molybdenum provide for resistance to nonoxidizing atmospheres.Upon exposure to oxidising agents, Inconel 625 is protected naturally by its nickel-chromium matrix. Meanwhile, molybdenum protects the material against pitting corrosion. In 15% sulfuric acid, the material corrodes at a minimal rate of 0.188 mm per year.

Chemical Analysis of Inconel 625 (%)

| Ni ≥ | Fe ≤ |

Cr |

Si ≤ |

Mo |

Mn ≤ |

C ≤ |

Al ≤ |

| 58 | 5 | 20 - 23 |

0.5 |

8 - 10 | 0.5 | 0.1 | 0.4 |

Mechanical Properties of Inconel 625

|

Ultimate Tensile Strength (Mpa) |

Elongation % |

Yield Strength MPa |

Density g/cm3 |

|

640 |

45 |

255 |

8.4 |

Related Category

CGI Spiral Wound Gasket

CG Spiral Wound Gasket

Vermiculite Filler Spiral Wound Gasket

Raw Materials for Spiral Wound Gasket

OFHC Copper Gasket For CF Flanges

Flange Isolation Gasket Kits

Rubber-steel Flange Gaskets

Ring Type Joint Gasket

Kammprofile Gaskets

Related Products