Hastelloy B3 Spiral Wound Gasket

Hastelloy® B-3 is a nickel- molybdenum alloy with excellent resistance to pitting, corrosion and stress-corrosion cracking

Content

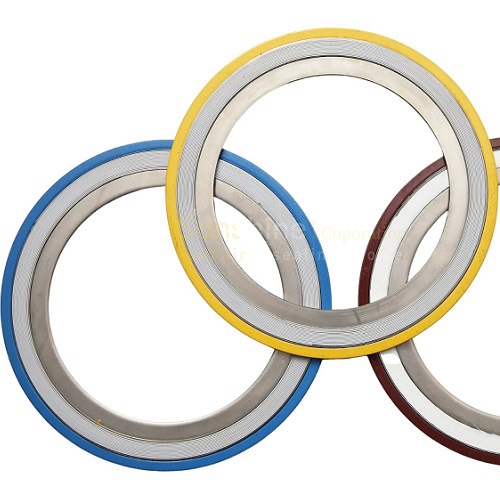

What is Hastelloy B3 Spiral Wound Gasket?

Hastelloy B3 spiral wound gasket consists of a winding ring made of V-shape Hastelloy B3 strip and PTFE filler, then combined with an inner ring or outer centering guide ring. Hastelloy B3 spiral wound gasket has excellent resistance to pitting, corrosion and stress-corrosion cracking and resistance to hydrochloric acid at all concentrations and temperatures.What is Hastelloy B3?

Hastelloy B-3 is a grade of Hastelloy which is a nickel-molybdenum alloy. There are many different grades of Hastelloy, which includes B-3. Grades of Hastelloy have each been optimized for a specific purpose. Molybdenum makes Hastelloy® harder and stronger at high temperatures.What's the Difference between Hastelloy B2 and B3?

The difference between Hastelloy B2 Hastelloy B3 is of importance to take into consideration. The thing about Alloy B2 and Hastelloy B3 is that both of these material give good resistance to non-oxidizing acids like sulfuric acid and hydrochloric acid. But the primary difference between both these types of material is that Hastelloy B3 offer fabrication characteristics that are improved and they also offer enhanced thermal stability. The alloy can be used in phosphoric acid and acetic acid and a range of organic acids. Hastelloy B2 alloy is having chloride induced SCC resistance.Application of Hastelloy B3 Spiral Wound Gasket

Hastelloy B3 spiral wound gaske can be used in chemical processing components, pollution control, oil and gas recovery, pickling tank parts and nuclear fuel processing.

Mechanical Properties of Hastelloy B3

| Ultimate Tensile Strength Ksi | Elongation % | Yield Strength Ksi | Density g/cm3 |

|

120 |

56 |

65 |

9.13 |

Related Category

CGI Spiral Wound Gasket

CG Spiral Wound Gasket

Vermiculite Filler Spiral Wound Gasket

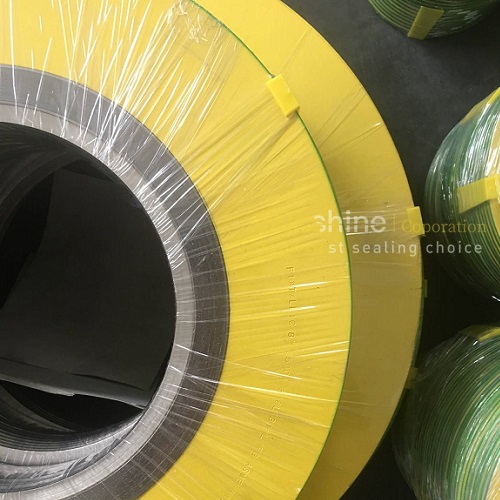

Raw Materials for Spiral Wound Gasket

OFHC Copper Gasket For CF Flanges

Flange Isolation Gasket Kits

Rubber-steel Flange Gaskets

Ring Type Joint Gasket

Kammprofile Gaskets

Related Products