Spiral Wound Gasket Bolt Torque Value Chart

2022-06-12

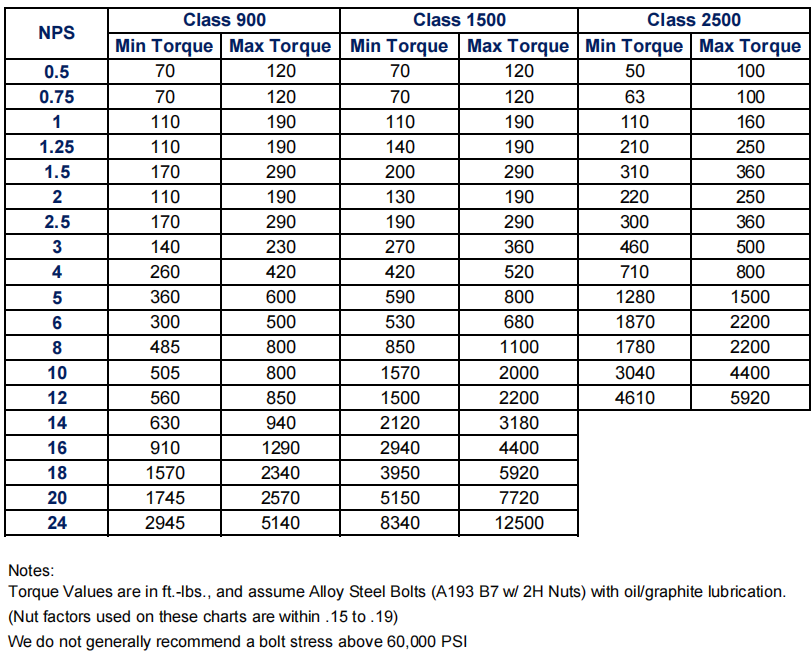

Here you will get the information about the recommended minimum spiral wound gasket bolt torque values for class 150, class 300, class 400, class 600, class 900, class 1500 and class 2500 spiral wound gaskets.

Spiral wound gasket bolt torque values are specified in ft-lb and N-m.

Bolting Recommendation

(1) when utilizing torque wrenches the use of suitable lubricants on the stud threads and nut bearing faces is recommended like molybdenum di-sulphide or nickel powder anti-seize compounds.(2) We recommend a 4 stage tightening methods as follows.

1. Tighten the bolts at 30% of the final loading using the diametrical sequence.

2. 60% of final load following diametrical sequence.

3. 100% of final load following diametrical sequence.

4. 100% of final torque on adjacent bolts.

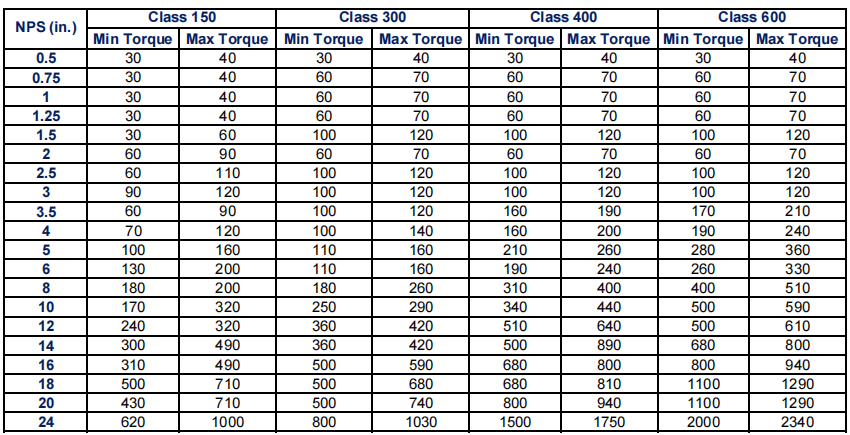

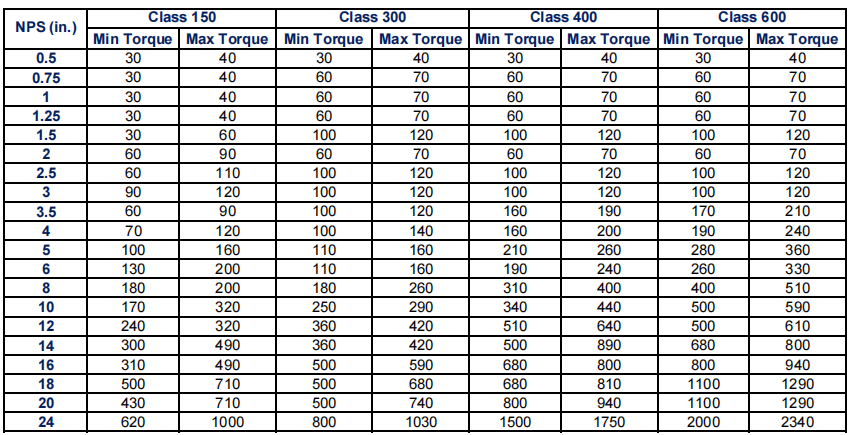

CG Spiral Wound Gasket with Outer Ring Torque Value

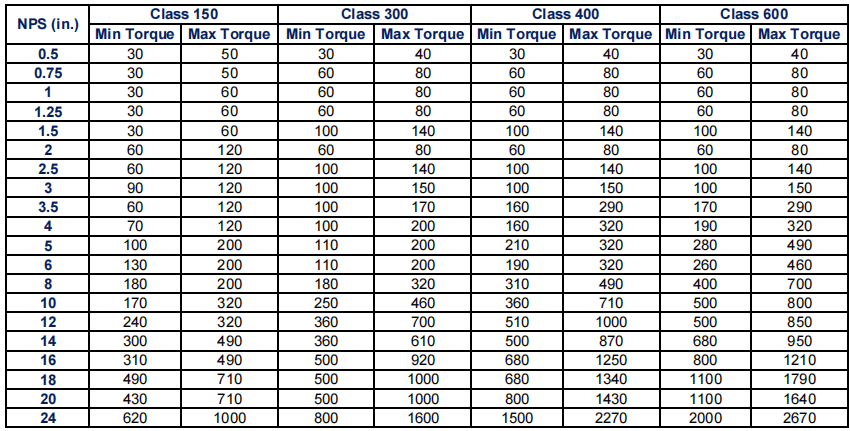

CGI Spiral Wound Gasket with Inner and Outer Ring Torque Value

Previous:Spiral Wound Gasket Weight Chart